Apparel manufacturing stands at the crossroads of tradition and innovation, weaving together the rich heritage of textile craftsmanship with the cutting-edge advancements of modern technology. This dynamic industry, pivotal to global economies and cultures, is undergoing transformative changes, driven by evolving consumer demands, technological breakthroughs, and an ever-pressing need for sustainability. In this comprehensive exploration, we delve into the intricacies of apparel manufacturing, from its foundational processes to the futuristic trends that are redefining what it means to create clothing in the 21st century.

Introduction to Apparel Manufacturing

Apparel manufacturing is the cornerstone of the fashion industry, encompassing a wide array of processes to convert raw materials into finished clothing items. This sector not only plays a significant role in the global market but also reflects societal trends, economic conditions, and technological advancements. The importance of apparel manufacturing extends beyond mere production; it is a pivotal element of cultural expression, economic development, and technological innovation.

The Process of Apparel Production

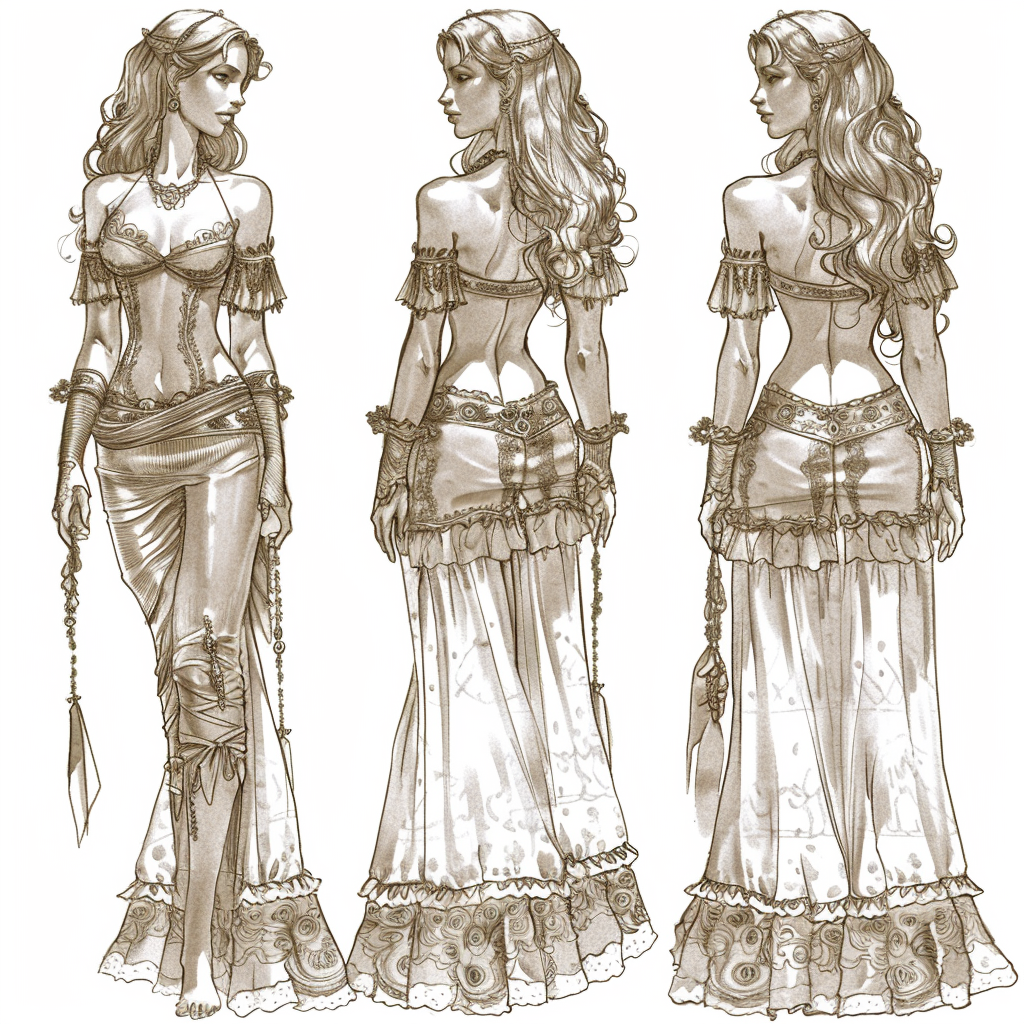

Design and Prototyping

The journey of apparel manufacturing begins with design and prototyping. This stage is where creativity meets practicality, and ideas are transformed into tangible products. Designers and engineers collaborate to create prototypes that balance aesthetic appeal with functionality, ensuring that each piece of clothing is both stylish and comfortable.

Material Sourcing and Selection

Selecting the right materials is crucial for quality apparel production. Manufacturers source fabrics and other materials based on criteria such as durability, comfort, and environmental impact. This step determines not only the feel and appearance of the final product but also its sustainability footprint.

Cutting and Sewing

The heart of apparel manufacturing lies in cutting and sewing, where pieces of fabric are intricately cut and meticulously assembled into garments. This process requires skilled craftsmanship and precision, ensuring that each garment meets strict quality standards.

Quality Control and Finishing

Before garments reach consumers, they undergo rigorous quality control checks and finishing touches. This ensures that the final products are of the highest quality, free from defects, and ready for the market.

Technological Advancements in Apparel Manufacturing

Automation in Sewing and Cutting

Technological advancements have revolutionized traditional sewing and cutting processes. Automation and robotics have introduced unparalleled efficiency and precision, reducing production times and minimizing human error.

Sustainable Technologies

The apparel industry is increasingly embracing sustainable technologies, from eco-friendly materials to water-saving dyeing techniques. These innovations not only reduce the environmental impact of manufacturing but also cater to the growing demand for sustainable fashion.

The Role of AI and Machine Learning

Artificial intelligence and machine learning are transforming apparel manufacturing, from predictive analytics in supply chain management to personalized design and production. These technologies enable manufacturers to anticipate market trends, optimize operations, and deliver customized products at scale.

Challenges Facing Apparel Manufacturers

Supply Chain Disruptions

Global supply chains are vulnerable to disruptions, from geopolitical tensions to natural disasters. Apparel manufacturers must navigate these challenges, ensuring continuity of operations while minimizing costs and delays.

Rising Costs of Materials

The fluctuating prices of raw materials pose a significant challenge for apparel manufacturers. Managing these costs while maintaining product quality and affordability is a delicate balance.

Labor Issues and Regulations

Labor practices and regulations vary widely across the globe. Manufacturers must adhere to ethical standards and labor laws, ensuring fair treatment of workers while competing in a cost-sensitive market.

Environmental Concerns

The environmental impact of apparel manufacturing is a growing concern. Manufacturers are under increasing pressure to adopt eco-friendly practices, from reducing waste to minimizing carbon emissions.

Apparel Manufacturing in China: An Overview

China’s apparel manufacturing industry is a global powerhouse, renowned for its supply chain efficiency, cost-effectiveness, and high-quality production. Chinese manufacturers leverage advanced technologies, skilled labor, and a comprehensive supply chain to deliver a wide range of apparel products to the global market. The advantages of manufacturing in China, particularly in hubs like Shanghai, are manifold, including access to a vast network of suppliers, competitive pricing, and rapid turnaround times.

Sustainable Practices in Apparel Manufacturing

Eco-friendly Materials and Processes

The shift towards sustainability is evident in the increasing use of eco-friendly materials and processes in apparel manufacturing. From organic cotton to recycled polyester, sustainable materials are becoming the norm, reducing the industry’s environmental footprint.

Ethical Labor Practices

Ensuring ethical labor practices is paramount in apparel manufacturing. This includes fair wages, safe working conditions, and respect for workers’ rights, reflecting the industry’s commitment to social responsibility.

Reducing Carbon Footprint

Manufacturers are adopting practices to reduce their carbon footprint, from energy-efficient production methods to logistics optimization. These efforts are crucial in mitigating the industry’s impact on climate change.

The Future of Apparel Manufacturing

The future of apparel manufacturing is shaped by the confluence of innovation, consumer demands, and sustainability. Technologies like 3D printing and smart textiles are opening new horizons for personalized and functional apparel. Meanwhile, the industry is moving towards a more sustainable and ethical model, reflecting a global shift towards environmental stewardship and social responsibility.

FAQs on Apparel Manufacturing

- What are the key factors to consider in apparel manufacturing?

- How is technology transforming apparel production?

- What steps are being taken to make apparel manufacturing more sustainable?

- How do manufacturers ensure the quality of their products?

- What are the challenges of sourcing materials for apparel manufacturing?

- How can consumers identify sustainably manufactured apparel?

Conclusion

Apparel manufacturing is at an exciting juncture, marked by rapid technological advancements, shifting market dynamics, and an increasing focus on sustainability. As the industry continues to evolve, the future holds promise for more innovative, efficient, and sustainable apparel production methods. By embracing change and adapting to new challenges, manufacturers can not only meet the demands of the modern consumer but also contribute to a more sustainable and ethical fashion industry.