OEM clothing, or Original Equipment Manufacturer clothing, plays a crucial role in the global fashion industry, offering an array of benefits for brands and manufacturers alike. This comprehensive guide delves into the essence of OEM clothing, exploring its advantages, the manufacturing process, and how it compares with ODM (Original Design Manufacturer). We’ll also tackle the challenges faced in OEM production and provide insights on selecting the right manufacturing partner to ensure success and sustainability in the highly competitive clothing market.

Introduction to OEM Clothing

OEM clothing refers to the process where a brand designs its apparel but outsources the manufacturing to an external company, which produces the clothing according to the brand’s specifications. This model allows clothing brands to leverage the manufacturing strengths of external factories while maintaining control over the design and quality of their products.

The Advantages of OEM for Clothing Brands

Choosing an OEM approach offers numerous advantages for clothing brands, including cost-effectiveness, quality assurance, and enhanced supply chain efficiency. By partnering with experienced manufacturers, brands can benefit from advanced production technologies and economies of scale, leading to reduced costs and improved product quality.

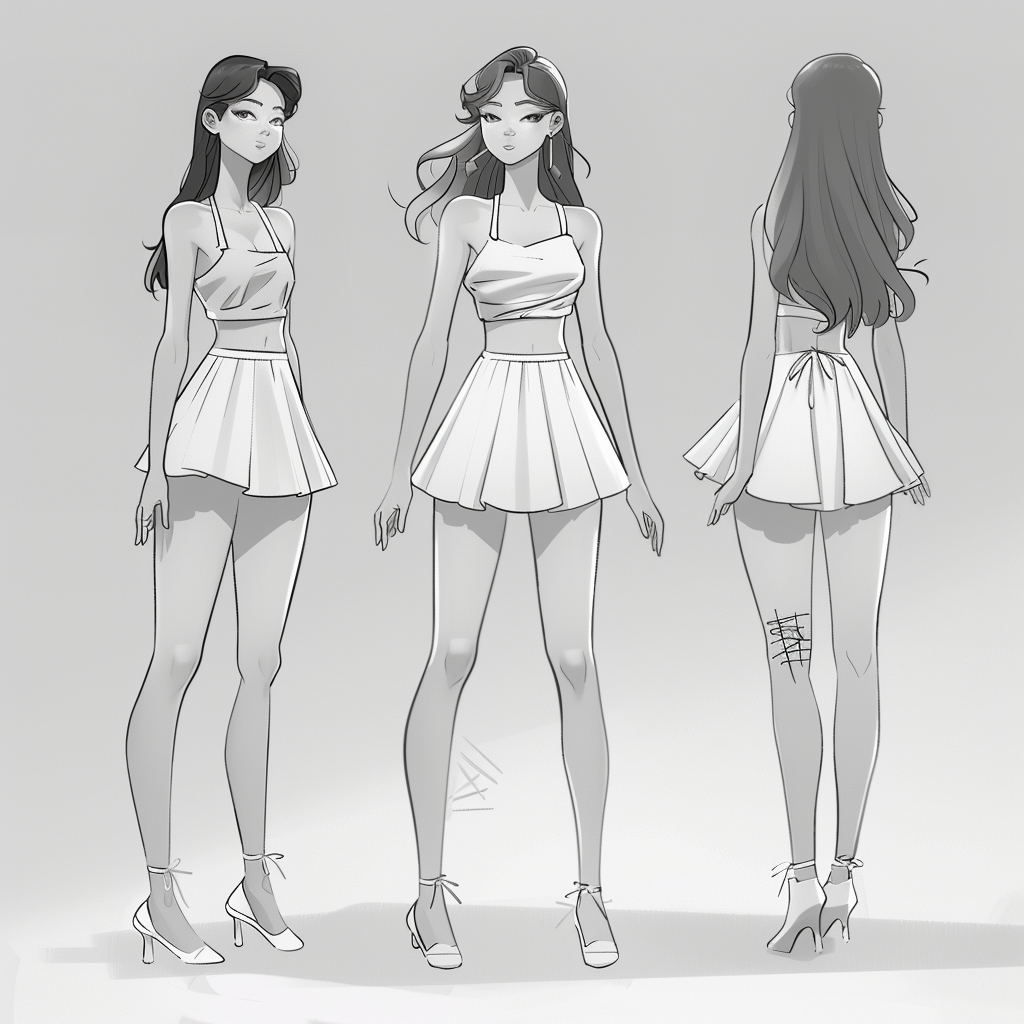

The Process of OEM Clothing Production

The journey of OEM clothing from concept to completion involves several key stages, including design conceptualization, material sourcing, and stringent quality control measures. This section will provide a step-by-step overview of the OEM clothing production process, highlighting the importance of each phase in ensuring the final product meets the brand’s standards.

OEM vs. ODM: Understanding the Differences

While OEM focuses on manufacturing products based on the brand’s designs, ODM involves purchasing off-the-shelf products that can be branded as the purchaser’s own. We will compare these two models, discussing their respective benefits and helping brands decide which approach best suits their needs.

Challenges in OEM Clothing Production

Despite its advantages, the OEM clothing production process can present several challenges, including communication barriers, quality control issues, and the need for flexibility in production schedules. This section will discuss strategies for overcoming these challenges to ensure a smooth and successful manufacturing partnership.

How to Choose the Right OEM Clothing Manufacturer

Selecting the right OEM partner is critical for a brand’s success. This section offers practical advice on assessing a manufacturer’s quality, reliability, cost-effectiveness, and commitment to ethical practices, ensuring a fruitful and sustainable partnership.

Case Studies: Success Stories in OEM Clothing

To illustrate the potential of successful OEM partnerships, this section will present real-world case studies of clothing brands that have thrived through strategic collaborations with OEM manufacturers.

Conclusion: The Future of OEM in Clothing

The final section will reflect on the evolving landscape of OEM clothing manufacturing, with a focus on emerging trends, such as the increasing emphasis on sustainability and ethical production practices. As the fashion industry continues to evolve, OEM clothing is set to play a pivotal role in shaping its future.