Introduction to OEM Protex Safety Clothing

OEM Protex safety clothing represents a crucial development in protective gear, combining advanced material engineering with stringent safety standards to offer superior protection in various industrial environments. OEM, or Original Equipment Manufacturer, signifies a company that produces parts and equipment that may be marketed by another manufacturer. Specifically, Protex fabric is renowned for its fire-resistant properties, making it an ideal choice for safety clothing.

What is OEM?

In the context of safety clothing, OEM refers to companies that design and manufacture safety apparel that is then branded and sold by other companies. This model allows for rigorous quality control and innovation in fabric technology, including the development of Protex, which is known for its durability and resistance to extreme conditions.

Introduction to Protex Material

Protex is a registered trademark material known for its fire-retardant properties. It is engineered to provide maximum protection against fire hazards, making it a popular choice in industries like firefighting, oil and gas, and electrical utilities. The material’s composition includes a blend of fibers that not only resist ignition but also effectively self-extinguish once the ignition source is removed.

The Importance of Safety Clothing

Safety clothing is an essential component of industrial safety, protecting workers from potential hazards associated with their specific work environments. The use of Protex safety clothing in various sectors underscores its significance in maintaining safety standards and complying with regulatory requirements.

Workplace Safety

Protex garments play a pivotal role in ensuring worker safety by providing a barrier against potential thermal hazards. These garments are specifically designed to meet the safety needs of workers exposed to high heat and flames, significantly reducing the risk of injuries.

Regulations and Standards

Safety clothing must adhere to various international safety standards, which specify the requirements for flame resistance, thermal protection, and durability. Protex safety clothing meets these rigorous standards, ensuring that it provides effective protection in compliance with industry regulations.

Protex Fabric: Composition and Benefits

The technical makeup of Protex fabric is what sets it apart in the safety clothing industry. Its unique properties not only ensure compliance with safety standards but also offer comfort and durability, making it suitable for extended wear in harsh environments.

Technical Specifications

Protex fabric is crafted from a blend of modacrylic fibers with other flame-resistant materials. This composition enhances the fabric’s ability to withstand high temperatures and resist fire without compromising on comfort or wearability.

Key Features

The key features of Protex safety clothing include high thermal resistance, excellent flame retardancy, and minimal shrinkage under extreme heat. Additionally, the fabric’s breathability and lightweight nature enhance user comfort, crucial for workers who wear these garments for long periods.

Manufacturing Process of OEM Protex Safety Garments

The manufacturing of OEM Protex safety clothing involves several critical steps, from design to production, ensuring that each garment meets the highest standards of safety and quality.

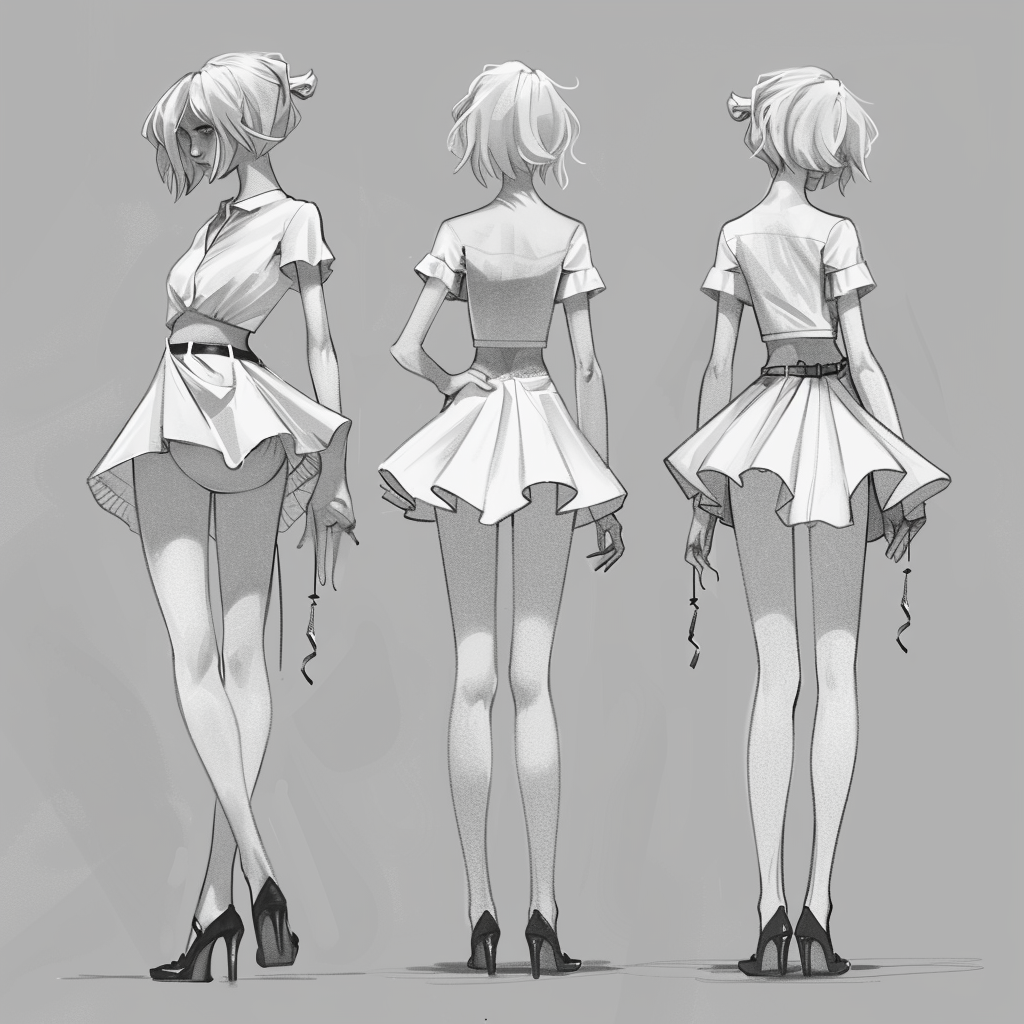

Design Considerations

When designing Protex safety clothing, manufacturers focus on both protection and functionality. This includes ergonomic features that enhance mobility and comfort, as well as the inclusion of reflective materials for increased visibility.

Production Techniques

Advanced manufacturing techniques, such as precision cutting and assembly, are employed to maintain the integrity of the Protex fabric. Special attention is given to seam construction, as these are critical points that must withstand extreme conditions without failing.

Applications of OEM Protex Safety Clothing

Protex garments are utilized across a broad range of industries, demonstrating their versatility and reliability in providing protection against fire and heat hazards.

Industries Using Protex

Key industries include oil and gas extraction, electrical utilities, and firefighting, where workers are regularly exposed to high-risk environments. Protex clothing offers these industries a reliable safety solution that significantly reduces the risk of injury.

Case Studies

Several case studies highlight the effectiveness of Protex safety clothing in real-world scenarios. For instance, in the oil and gas industry, Protex garments have been credited with preventing serious injuries in fire-related incidents, showcasing their protective capabilities.

Choosing the Right OEM Safety Clothing

Selecting the appropriate safety clothing is crucial for ensuring maximum protection and compliance with industry standards.

Factors to Consider

When choosing Protex safety clothing, it’s important to consider factors such as the specific hazards of the workplace, the required level of protection, and the clothing’s compatibility with other protective equipment.

Maintenance and Care

Proper maintenance and care of Protex clothing are vital for preserving its protective qualities. Regular cleaning and inspection procedures should be followed, as specified by the manufacturer, to ensure the garments maintain their effectiveness.

Conclusion and Future Trends

As the demand for effective safety clothing continues to grow, so does the innovation within the industry. Protex is at the forefront of this development, continually advancing the technology behind their safety garments.

Recent Developments

Recent advancements in Protex technology include improvements in fabric composition for enhanced fire resistance and reduced environmental impact. These developments not only improve safety but also contribute to sustainability in the manufacturing process.

Future Outlook

The future of OEM Protex safety clothing looks promising, with ongoing research and development aimed at enhancing the protective properties of the fabric while maintaining environmental responsibility. As new standards and technologies emerge, Protex is well-positioned to continue leading the market in high-quality, high-performance safety garments.

FAQs

What makes Protex material suitable for safety clothing? Protex’s unique blend of fire-resistant fibers provides exceptional protection against fire hazards, making it suitable for industries where fire risk is a concern.

How does OEM play a role in safety clothing? OEMs are responsible for the design and manufacture of safety clothing, ensuring that the garments meet all safety standards and regulations before being branded and sold by other companies.

What are the key features of Protex safety clothing? Key features include high thermal resistance, flame retardancy, and comfort, making Protex garments ideal for prolonged use in hazardous conditions.

Where is Protex safety clothing commonly used? It is commonly used in industries such as oil and gas, firefighting, and electrical utilities, where there is a significant risk of fire and heat exposure.

How should Protex safety garments be maintained? Regular cleaning and inspection as specified by the manufacturer are essential to maintain the protective qualities of the garments.

What are the future developments expected in the field of safety clothing? Future developments may include enhancements in fabric technology for better protection and sustainability, addressing both safety and environmental concerns.