Introduction to OEM Apparel Manufacturers

OEM (Original Equipment Manufacturer) apparel manufacturers play a pivotal role in the fashion industry by producing clothing that other companies brand and sell. This partnership allows brands to focus on design and marketing, leveraging the manufacturing expertise of OEMs to ensure product quality and efficiency.

What is OEM?

OEM stands for Original Equipment Manufacturer, referring to companies that produce products or components that are purchased by another company and retailed under that purchaser’s brand name. In the apparel industry, this means manufacturing clothing that meets the branding and quality standards of another company.

Role in the Apparel Industry

OEM manufacturers are crucial for many fashion brands, especially those that do not own production facilities. They provide the resources necessary to produce large volumes of apparel while managing the complexities of garment manufacturing.

Key Advantages of Partnering with OEM Manufacturers

Collaborating with an experienced OEM can offer numerous benefits to fashion brands, from cost savings to enhanced product quality.

Cost-Effectiveness

OEM manufacturers can produce large quantities of garments at a lower cost due to their scaled operations and specialized equipment, offering a cost-effective solution for apparel brands.

Access to Expertise

These manufacturers bring years of expertise in various aspects of garment production, from material sourcing to complex assembly processes. This expertise ensures high-quality outcomes and can help brands navigate any production challenges.

The Production Process in OEM Apparel Manufacturing

Understanding the production process managed by OEMs can help brands ensure that their garments are made to the highest standards.

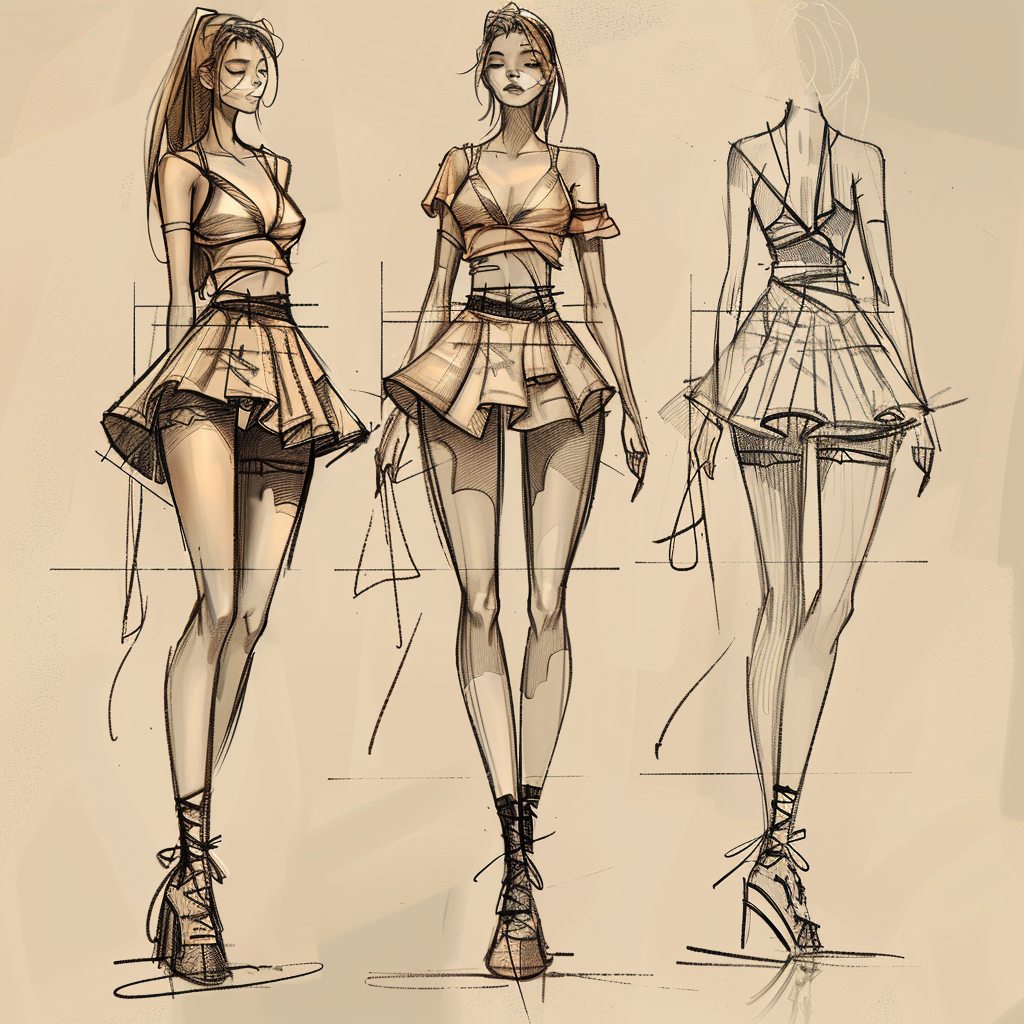

Steps from Design to Delivery

The process typically starts with the brand providing the designs and specifications. The OEM then sources materials, produces samples for approval, and upon receiving the go-ahead, begins mass production. This phase is followed by quality checks and finally, distribution.

Quality Assurance

Quality assurance is integral to OEM manufacturing. Rigorous testing and evaluations are conducted at various stages of production to ensure that the final products meet the required quality standards.

Criteria for Selecting an OEM Manufacturer

Choosing the right OEM manufacturer is crucial for maintaining the quality and reputation of a brand.

Experience and Reputation

The experience and reputation of an OEM manufacturer can significantly influence the quality of the produced apparel. Brands should look for manufacturers with a proven track record and positive industry reputation.

Production Capabilities

It’s important to assess the production capabilities of an OEM, including their ability to scale operations, adapt to different garment types, and handle specific materials or designs.

Challenges Faced by OEM Apparel Manufacturers

Despite the advantages, OEM manufacturers face several challenges that can impact production and delivery.

Supply Chain Management

Effective supply chain management is critical, especially in a global market. OEMs must manage logistical challenges, maintain inventory levels, and ensure timely delivery of components and finished products.

Adapting to Market Changes

The fashion industry is fast-paced, requiring OEMs to continually adapt to changing fashion trends, consumer demands, and technological advancements.

Innovations in OEM Apparel Manufacturing

Technological and sustainable innovations are increasingly becoming a part of OEM manufacturing strategies.

Technological Advances

Advanced technologies like automation, AI in production processes, and 3D printing are transforming apparel manufacturing, making it faster and more cost-efficient.

Sustainable Practices

There is a growing emphasis on sustainability within the industry. OEMs are adopting eco-friendly practices, such as using sustainable materials and reducing waste, to meet both consumer expectations and regulatory requirements.

The Future of OEM Apparel Manufacturing

The future of OEM in apparel looks promising with several trends expected to shape the industry.

Market Trends

As the market evolves, OEMs will need to focus more on flexibility, speed to market, and customization to meet the changing needs of apparel brands.

Evolving Business Models

The shift towards more sustainable and technologically advanced manufacturing processes is likely to continue, driving OEMs to innovate and possibly restructure their business models to stay competitive.

FAQs

What is the difference between OEM and ODM in apparel manufacturing? OEM involves manufacturing products as per the specifications provided by another company, while ODM (Original Design Manufacturer) includes designing the product as well as manufacturing it.

How do OEM manufacturers ensure product quality? OEM manufacturers implement rigorous quality control procedures throughout the production process, including regular inspections and testing of materials and finished products.

What should brands consider when choosing an OEM manufacturer? Brands should consider the manufacturer’s experience, production capabilities, scalability, commitment to quality, and their ability to meet deadlines.

How are OEM manufacturers adapting to the demand for sustainability? Many OEMs are integrating sustainable practices into their operations, such as using eco-friendly materials and optimizing production processes to minimize waste.

What are the future trends in OEM apparel manufacturing? Future trends include the increased use of automation and AI, a stronger focus on sustainability, and a shift towards more flexible and responsive manufacturing practices.