Introduction to High-Quality Wholesale Knitted Zipper Apparel OEM Factory

A high-quality wholesale knitted zipper apparel OEM (Original Equipment Manufacturer) factory is crucial in the apparel industry, providing the expertise and infrastructure necessary to produce large volumes of specialized clothing. These factories enable brands to outsource production while maintaining their product standards and brand essence.

Definition of OEM Factory

An OEM factory manufactures products that are then sold under another company’s brand name. In the context of apparel, such factories produce clothing that is designed and branded by other businesses.

Role in Apparel Production

OEM factories are pivotal in transforming creative designs into market-ready products, especially in niche categories like knitted zipper apparel. They not only offer production services but also contribute to material sourcing, product development, and quality assurance.

Benefits of Using a Specialized OEM Factory

Partnering with a specialized OEM factory comes with significant advantages, particularly for brands looking to expand or maintain a presence in the competitive apparel market.

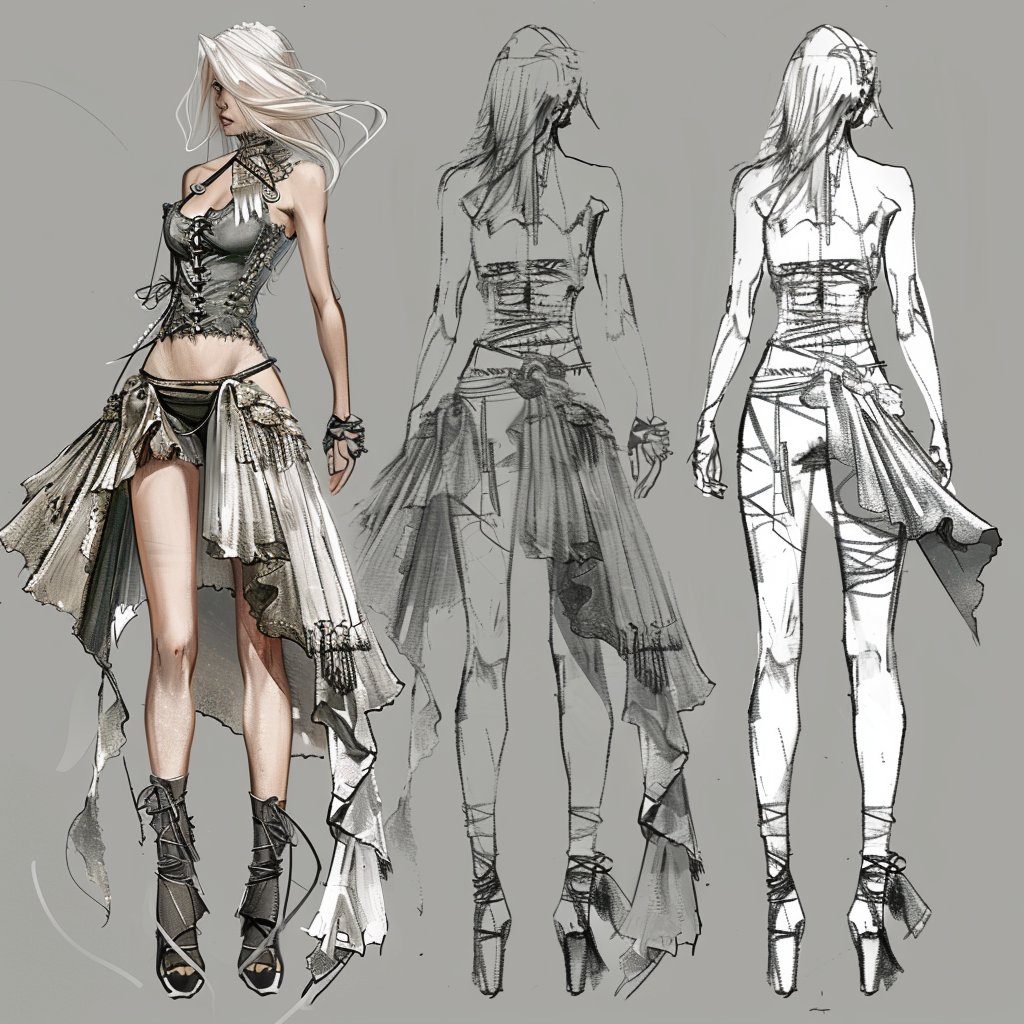

Expertise in Knitted Zipper Apparel

OEM factories specializing in knitted zipper apparel possess specific skills in seamlessly integrating zippers into various knits, which can range from lightweight synthetics to more substantial wool blends. This expertise ensures that the final products are both functional and fashionable.

Cost Savings

By leveraging economies of scale and advanced manufacturing processes, these factories can produce large orders at a lower cost, enabling brands to price their products competitively in the market.

Critical Features of a High-Quality OEM Factory

The effectiveness of an OEM factory is often reflected in its operational features and capabilities, which directly impact the quality and appeal of the produced apparel.

Advanced Manufacturing Capabilities

Top-tier OEM factories are equipped with state-of-the-art knitting and sewing machines, automated systems for zipper integration, and sophisticated logistics for efficient production flows.

Quality Control Standards

Stringent quality control is integral to the operations of high-quality OEM factories. Regular audits, multi-stage quality checks, and adherence to international standards ensure that each product batch meets the required specifications.

The Production Process in a Knitted Zipper Apparel OEM Factory

Understanding the production process in these factories provides insight into how designs are brought to life with precision and efficiency.

Design to Delivery Workflow

The process begins with client consultations to finalize designs, followed by prototyping, bulk material procurement, production scheduling, and finally, manufacturing. Each stage is closely monitored to ensure adherence to the client’s requirements.

Integration of Zippers in Knitting

Integrating zippers into knitted apparel requires precise machinery and skilled technicians. The OEM factory handles this integration seamlessly, ensuring that zippers are both aesthetically pleasing and functional, enhancing the garment’s overall design.

Challenges Faced by OEM Factories

Despite their capabilities, OEM factories face several challenges that can affect their efficiency and output.

Supply Chain Management

Managing a global supply chain for materials like yarns, zippers, and other accessories can be complex due to fluctuating prices, varying quality standards, and logistical delays.

Adapting to Fast Fashion Cycles

Keeping pace with the rapid cycles of the fashion industry requires OEM factories to be extremely agile, often necessitating quick turnovers and adaptive production strategies.

Best Practices in Selecting an OEM Factory

Choosing the right OEM factory is critical for apparel brands that rely on outsourced manufacturing for their products.

Criteria for Selection

Key selection criteria should include the factory’s production capacity, past clients, quality of produced garments, compliance with labor laws, and environmental standards.

Assessing Capabilities and Compliance

Visiting the factory, reviewing third-party audits, and checking certifications are all vital steps in assessing whether an OEM factory aligns with a brand’s values and quality expectations.

Future Trends in Apparel Manufacturing

The landscape of apparel manufacturing is constantly evolving, driven by new technologies and a shift towards more sustainable practices.

Sustainability Initiatives

More OEM factories are adopting sustainable practices, such as using recycled materials, reducing waste, and minimizing water usage, to appeal to environmentally conscious brands and consumers.

Technological Innovations

Advancements in textile technology, including automated knitting machines and AI-driven production planning, are set to transform apparel manufacturing, making it faster, more precise, and cost-effective.

FAQs

What does an OEM factory do in the apparel industry? An OEM factory manufactures clothing that other companies design and sell under their own brands, handling everything from material sourcing to the final production.

Why are specialized OEM factories preferred for knitted zipper apparel? Specialized OEM factories have the specific machinery and expertise needed to integrate zippers into knits effectively, ensuring high-quality and functional products.

What are the key features to look for in a high-quality OEM factory? Key features include advanced manufacturing technologies, rigorous quality control standards, and the ability to handle large-scale production efficiently.

How do OEM factories handle the integration of zippers in knitted apparel? They use specialized sewing and integration techniques to ensure that zippers are added without compromising the integrity or appearance of the knitted fabric.

What future trends are shaping OEM apparel manufacturing? Future trends include a greater focus on sustainability and the integration of cutting-edge technologies to enhance production capabilities and meet changing market demands.