Introduction to a Wholesale High-Quality Knitted Zipper Apparel OEM Factory

In today’s competitive apparel industry, specialized manufacturing processes like those found in a wholesale high-quality knitted zipper apparel OEM factory are crucial for brands looking to deliver innovative and quality products. These factories are the backbone of many popular clothing lines, providing scalability and expertise that drive the fashion industry forward.

Overview of OEM Factories

Original Equipment Manufacturer (OEM) factories produce products that other companies design and sell under their own brands. This collaboration allows brands to leverage advanced manufacturing resources without the overhead of maintaining full-scale production facilities.

Importance in the Apparel Market

Knitted zipper apparel, popular in both athletic and casual wear, requires precise manufacturing techniques. OEM factories specializing in this type of apparel use their expertise to ensure high-quality production that meets global standards and consumer expectations.

Advantages of Using a Wholesale OEM Factory for Knitted Zipper Apparel

Partnering with a seasoned OEM factory comes with significant benefits, crucial for maintaining a competitive edge in the dynamic fashion market.

Cost-Effectiveness

Wholesale OEM factories offer cost-effective production solutions by leveraging economies of scale, which can significantly reduce the overall production cost per unit for apparel brands.

Enhanced Production Capabilities

These factories are equipped with state-of-the-art machinery and technology that streamline the production process, from raw materials to finished products, ensuring efficiency and high output rates.

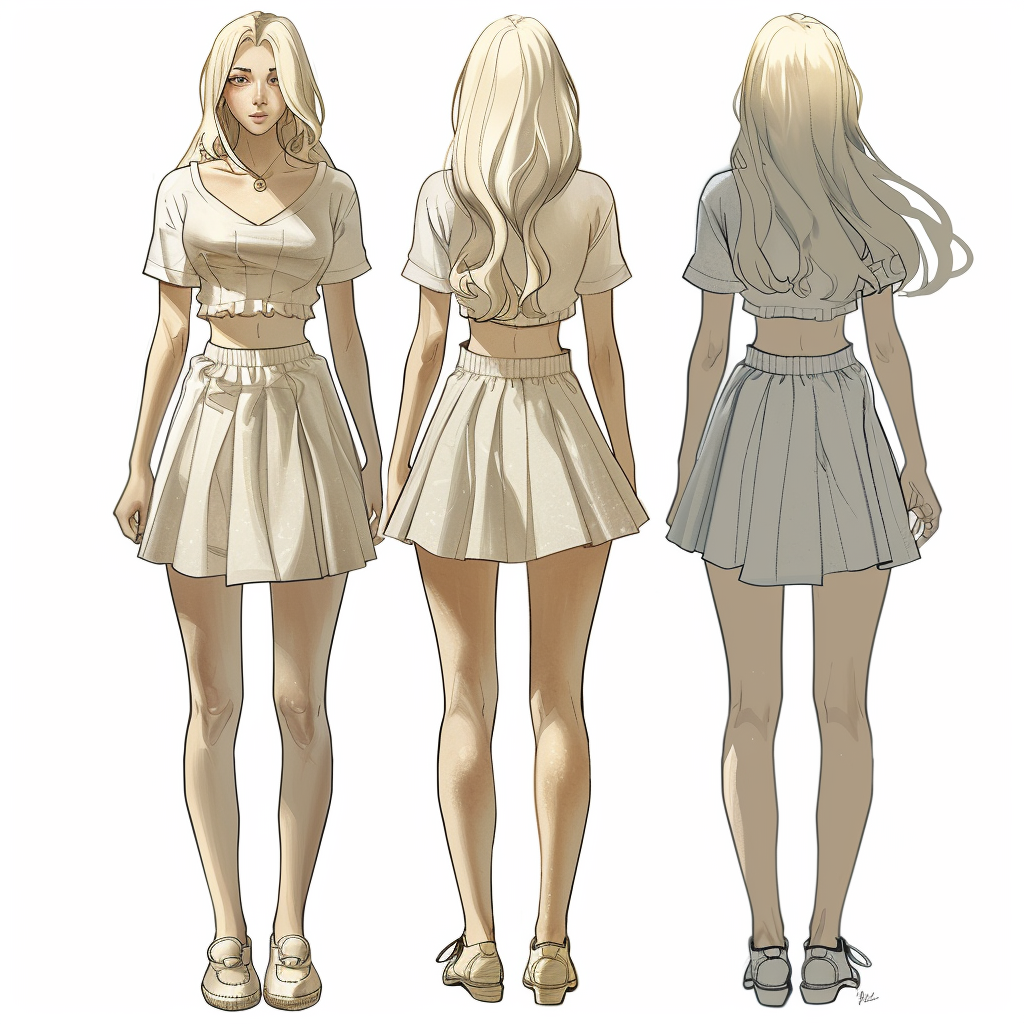

Key Features of Knitted Zipper Apparel from an OEM Factory

The success of knitted zipper apparel lies in the quality of its production, which is meticulously managed to meet specific industry and consumer standards.

Material Quality

High-quality yarns and zippers are selected to ensure durability, comfort, and functionality. The choice of materials significantly affects the final product’s appeal and performance.

Design Innovations

OEM factories collaborate closely with brands to refine designs that enhance both aesthetic appeal and practical utility, incorporating features like seamless zippers that blend flawlessly with the knit fabric.

Manufacturing Process in a Wholesale OEM Factory

Understanding the manufacturing process provides insight into the meticulous attention to detail involved in producing knitted zipper apparel.

Detailed Production Steps

The production process includes several stages: yarn selection, knitting, dyeing, cutting, sewing, and final assembly. Each phase is critical and requires precise execution to maintain the integrity of the design and functionality.

Quality Control and Assurance

Rigorous quality control measures are implemented throughout the production process to ensure each garment meets predefined standards. This includes continuous monitoring and testing of the fabric’s performance and the zipper’s functionality.

Challenges in the Wholesale Knitted Zipper Apparel Production

Despite the advantages, there are inherent challenges faced by OEM factories specializing in knitted zipper apparel.

Consistency and Quality Maintenance

Maintaining consistency in quality across large production volumes can be challenging, especially when balancing fast production turnaround times with high-quality outputs.

Supply Chain Complexities

Navigating the complexities of the global supply chain, from sourcing raw materials to timely delivery of finished products, remains a significant challenge for wholesale OEM factories.

How to Choose the Right Wholesale OEM Factory

Selecting the right OEM factory is crucial for brands looking to forge a successful and profitable partnership.

Criteria for Selection

Key criteria include the factory’s technological capability, production capacity, past client testimonials, adherence to safety and environmental regulations, and the ability to meet deadlines consistently.

Assessing Factory Competencies

Visiting the factory, reviewing samples of previous work, and assessing the transparency of their production processes are essential steps in evaluating a potential OEM partner.

Future Trends in Knitted Zipper Apparel Manufacturing

The manufacturing landscape is continuously evolving, driven by innovations and shifting market demands.

Technological Advancements

Advancements in knitting and sewing technology, such as automated systems and AI-driven production lines, are set to enhance production efficiency and product quality.

Sustainability and Eco-friendly Practices

An increasing focus on sustainability is pushing OEM factories to adopt eco-friendly practices, such as using recycled materials and reducing waste, which is becoming a deciding factor for many brands in their OEM selection process.

FAQs

What is an OEM factory? An OEM factory designs and manufactures products that are marketed and sold under another company’s brand name.

Why are knitted zipper apparel popular? Knitted zipper apparel offers a combination of comfort, versatility, and style, making it popular in both sportswear and casual fashion segments.

What should brands consider when choosing an OEM factory? Brands should consider the factory’s production capabilities, quality control standards, scalability, and their commitment to sustainable manufacturing practices.

What are the future trends in apparel manufacturing? Future trends include increased automation, integration of advanced technologies, and a strong emphasis on sustainability and ethical manufacturing.