Introduction to Wholesale OEM Knitted Zipper Apparel

In the ever-evolving fashion industry, knitted zipper apparel stands out for its blend of comfort and functionality. Wholesale Original Equipment Manufacturer (OEM) facilities play a pivotal role in the production of these garments, allowing brands to outsource manufacturing to specialists who can handle large-scale production efficiently.

What is OEM?

OEM refers to the process of producing goods that will be marketed under another company’s branding. This collaboration allows brands to leverage external expertise and advanced manufacturing facilities without direct investment in production infrastructure.

Importance of OEM in Apparel Industry

For apparel companies, especially those dealing with specialized products like knitted zipper apparel, OEM partnerships are essential. They offer a way to scale production, maintain quality, and respond flexibly to market demands and fashion trends.

Benefits of Using a Wholesale OEM for Knitted Zipper Apparel

Partnering with a wholesale OEM offers distinct advantages for brands looking to expand or maintain a competitive edge in the marketplace.

Cost Efficiency

OEMs provide cost-effective solutions by handling bulk production orders, benefiting from economies of scale that individual brands might not achieve on their own.

Access to Specialized Expertise

OEMs specializing in knitted zipper apparel bring extensive experience and technical skills to the table, ensuring that products are not only of high quality but also incorporate the latest industry innovations.

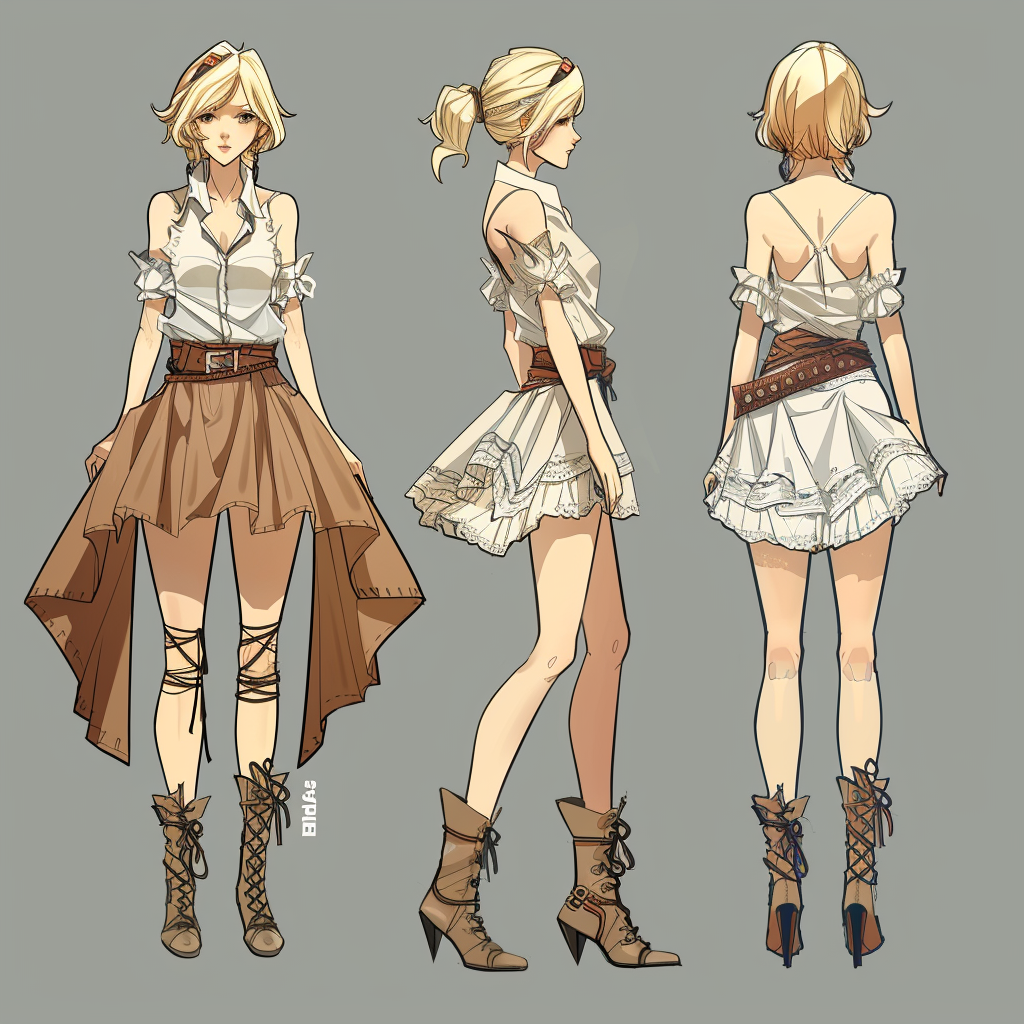

Key Features of High-Quality Knitted Zipper Apparel

The appeal of knitted zipper apparel lies in its detailed craftsmanship and the quality of its components.

Material and Fabric Quality

Top-tier OEMs use premium materials that enhance the durability, feel, and overall performance of the apparel, ensuring products meet consumer expectations for high-quality garments.

Design and Functional Integration

Effective integration of zippers into knit fabrics without compromising the integrity and aesthetic of the design is a hallmark of skilled OEM production. This includes seamless incorporation of zippers for both functionality and style.

The OEM Production Process for Knitted Zipper Apparel

Understanding the production process is crucial for brands to ensure their specifications are met accurately.

Design to Production Steps

The process starts with prototype development based on the brand’s designs, followed by material sourcing, production planning, and the actual manufacturing. This systematic approach helps in maintaining quality consistency.

Quality Control Measures

Rigorous quality assurance at every step ensures that each batch of the knitted zipper apparel adheres to the high standards expected by clients and their customers.

Challenges in the Wholesale OEM Production of Knitted Zipper Apparel

Despite the benefits, producing knitted zipper apparel on a wholesale scale presents several challenges.

Maintaining Quality and Consistency

Ensuring each garment meets the set quality standards consistently across large production volumes can be challenging, requiring robust quality control systems.

Supply Chain and Logistics Management

Effective management of supply chains and logistics is critical, especially with the complexities of global manufacturing and distribution networks.

How to Choose the Right Wholesale OEM for Knitted Zipper Apparel

Selecting the right OEM partner is critical for ensuring product quality and supply reliability.

Criteria for Selection

Important criteria include the manufacturer’s capacity, production and delivery timelines, past client experiences, and adherence to ethical manufacturing practices.

Evaluating Manufacturer’s Track Record

Assessing the potential OEM’s portfolio, client testimonials, and visiting the production facilities can provide deeper insights into their operational capabilities and product quality.

Future Trends in Knitted Zipper Apparel Manufacturing

The future of knitted zipper apparel manufacturing is likely to be shaped by technological advancements and a growing emphasis on sustainability.

Innovations in Textile Technology

Advancements such as 3D knitting and automated sewing are set to improve production efficiency and customization capabilities.

Sustainability in Apparel Production

An increasing focus on sustainable practices is driving OEMs to adopt eco-friendly materials and processes, reducing the environmental impact of apparel production.

FAQs

What makes OEM an attractive option for apparel brands? OEM allows apparel brands to leverage external manufacturing expertise, achieve economies of scale, and focus on core competencies like design and marketing.

How do OEMs ensure the quality of knitted zipper apparel? OEMs implement stringent quality control protocols throughout the production process, from the sourcing of materials to the final stitching and assembly of garments.

What should brands look for when choosing an OEM partner? Brands should evaluate an OEM’s production capacity, quality assurance standards, flexibility in order processing, and commitment to sustainable practices.